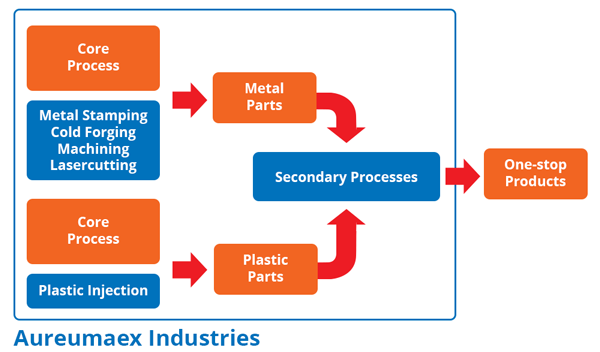

We Provide All-in-one Service

The hallmark of our service is to tailor the need for fast and flexible process that gives you what you want, when you want it, at the highest quality and affordable cost. All these grant you with an incredible opportunity to manage and strengthen your supply chain management seamlessly without incurring additional resources. What you need is to only manage one supplier for all industrial fields that you are looking for.

Through our all-in-one service, we see ourselves as more than just an ordinary provider but one that can truly create value for your businesses to become more competitive within your respective market. We strive earnestly to provide and assure our best-in-class service and product quality which are strongly embodied within our brand promise that we will steadfastly deliver. We are fully committed to your success and satisfaction.

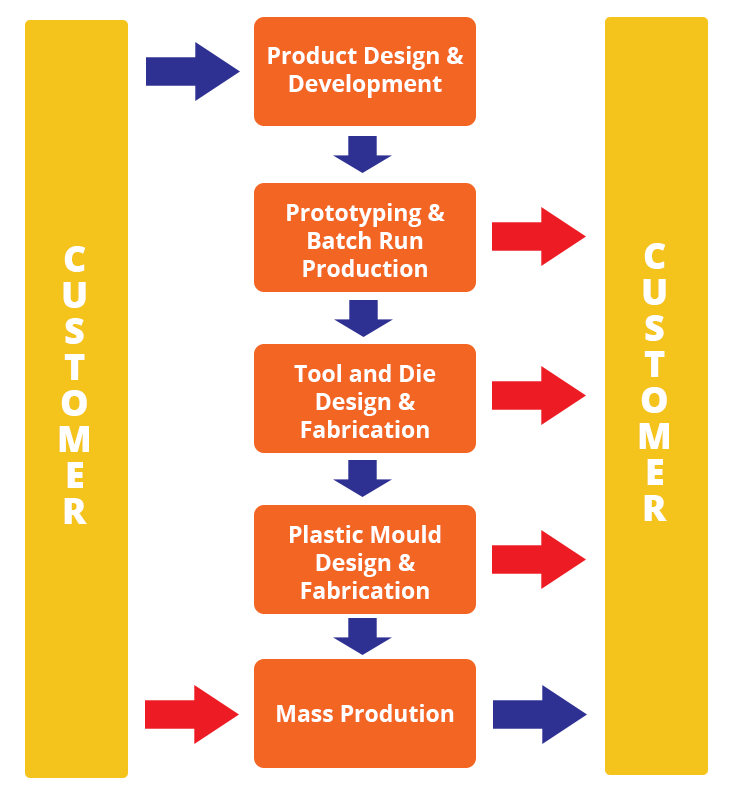

Total integrated manufacturing solution

Product Design and Development

We perform product review and analysis to enhance:

- Design for manufacturability which the products are manufactured practically

- Design for quality and reliability which the products are manufactured towards zero defect and failure

- Design for productivity which the products are produced effectively and efficiently

Prototyping and Batch Run Production

We also provide batch run production service to cater your requirements at low volume of production. This will enable you to manufacture your products at lowest possible cost without high investment in hard tool fabrication.

We have a special and independent group of workforce to handle prototyping and batch run production. We are well- equipped with a comprehensive range of machineries, soft tools, jigs, fixtures and secondary operations that can turn over your samples or batch products in a relatively short time.

Tool and Die Design and Fabrication

We provide design and fabrication of tool and die for metal stamping process, either manual or progressive, up to 600 tons-capacity. This is our specialty that we earn reputation from global market.

We are capable to design and fabricate tool and die to meet your customized specifications, such as size, concept and life of tool, at your affordable cost. All our design and fabrication are made according to common industrial standard that you can fit into any brand of press machines or you can easily replace its accessories in the market. We will justify, ensure and maintain the condition of tool as per your requirements for an agreed guaranteed quantity.

You can engage our service of tool and die design and fabrication merely and we will deliver back the tool, as product, to you upon completion of fabrication. Or, you can engage us not only to design and fabricate the tool, but also for the mass production after completion of tool fabrication.

We also provide design and fabrication of tool and die for cold forging process, to serve as alternative process for customers. The cold forging process is designed to reduce or eliminate the need of secondary processes such as machining, buffing, etc., compared to metal stamping process. This value-added process will indirectly benefit you from cost saving in your products.

We also establish our design and fabrication of tool and die in the stamping of printed circuit board (PCB). It creates opportunity for you to assemble and integrate your electronic components with our precision metal or plastic parts at the same time for the ease of managing your product flow.

With our fully integrated computer-aided design and manufacturing (CAD/CAM) facilities, we are capable to produce our design and fabrication of tool and die promptly. We believe that our design and fabrication capabilities will contribute to our continued competitiveness in providing lowest possible cost and shortest possible time to customers.

Plastic Mould Design and Fabrication

We extend our similar service in tool and die to plastic mould design and fabrication. Our Plastic Division is capable to design and fabricate plastic injection or compression mould which can be ranged up to 1300 tons-capacity, to meet all your increasingly stringent requirements of products.

Our Plastic Division have an independent team of designers, engineers and mould makers to oversee the activities of design and fabrication without any conflict of interest with others, and, thus able to produce excellent job for customers.

With our combined capabilities in metal and plastic, we are confident to offer you with attractive package that able to integrate your precision metal and plastic components into one-stop products at one location with one supplier.

Mass Production

Our services of mass production can be summarized in the followings: